Contact phone number

乐发lx+8613905342326

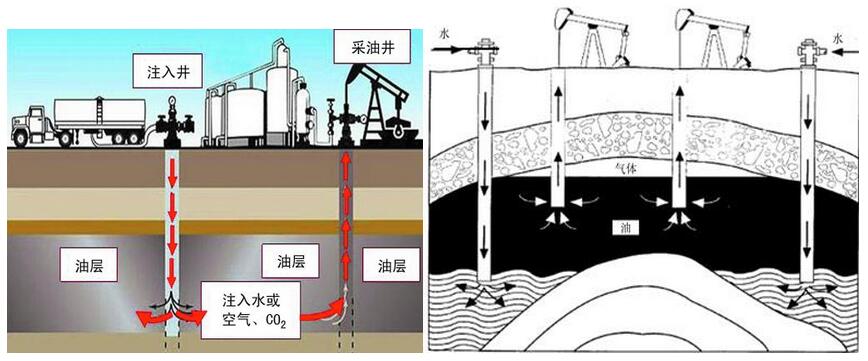

1、 The necessity of water injection development

&Nbsp& Nbsp& Nbsp; At present, after the oilfield is put into development, as the extraction time increases, the energy of the oil layer itself will continue to be consumed, resulting in a continuous decrease in the pressure of the oil layer, a large amount of degassing of underground crude oil, an increase in viscosity, a significant reduction in oil well production, and even the cessation of injection and production, resulting in a large amount of residual dead oil underground that cannot be extracted.

&Nbsp& Nbsp& Nbsp; In order to compensate for the underground deficit caused by crude oil extraction, maintain or increase reservoir pressure, achieve high and stable oil production in the oilfield, and achieve high recovery rates, it is necessary to inject water into the oilfield.

&Nbsp& Nbsp& Nbsp; 2、 Device Overview

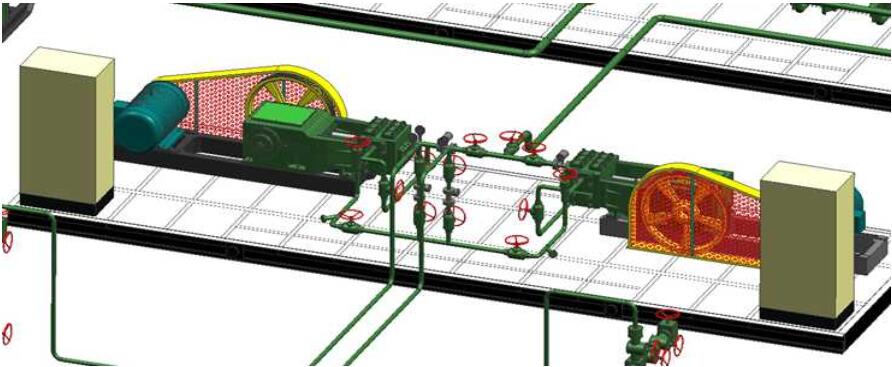

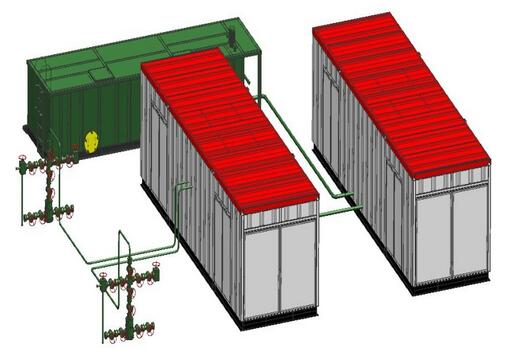

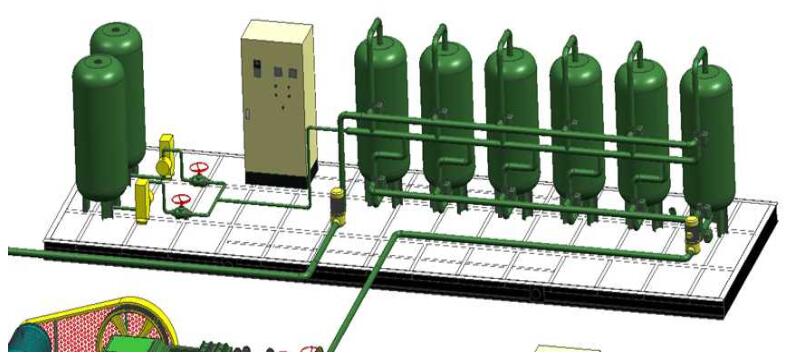

&Nbsp& Nbsp& Nbsp& Nbsp;Mobile pry mounted integrated water injection deviceIt is a complete set of pry mounted water injection device designed and developed by our company, which meets the construction process requirements of advanced water injection and edge small block water injection in the early stage of oilfield development. This device meets the requirements of standardized design and modular construction. The water tank, water treatment device, water injection pump, etc. are designed as a lever, which can be relocated and reused as a whole. It has high integration, convenient operation, reliable and safe operation, and significantly reduces the investment of fixed water injection stations. This device can be designed and manufactured according to the requirements of the water injection process, with one or more prys; Can achieve fully automatic and semi-automatic control according to customer requirements; The water treatment process can be reasonably configured according to water quality requirements to achieve primary or multi-level treatment.

&Nbsp& Nbsp& Nbsp; 3、 Device composition

&Nbsp& Nbsp& Nbsp; The device mainly consists of oil wastewater treatment tank and fineFilter leverBlock, water injection pump pry block composition. Including: unloading pumpWater storage tankWater treatment additive feedingequipmentMulti medium filter, diamond sand filter, fine filter, clean water tank, feeding pump, water injection pump, manifold, instrumentvalveControl system, power distribution system, pneumatic system, etc. (equipment can be added or reduced according to the actual water injection process design combination). The entire device has high filtration accuracy (A1 grade effluent water quality); Long service life (corrosion resistance, backwashing, filter material regeneration); Blocked connection, easy to operate.

&Nbsp& Nbsp& Nbsp; 4、 Device Configuration Description

&Nbsp& Nbsp& Nbsp; 1. Sewage tank pry block& Nbsp& Nbsp& Nbsp; The sewage tank pry block mainly consists of unloading pump, sewage tank, and intelligent magnetic flip plateLiquid level gaugeThe main function of the system is to maintain uninterrupted and continuous water supply, which is composed of (output signal: switch quantity) and manifold valves. The sewage tank is equipped with an intelligent magnetic flap level gauge, which has a high and low liquid level alarm function.

&Nbsp& Nbsp& Nbsp; 2. Oil containing wastewater treatment tank pry block& Nbsp& Nbsp& Nbsp; The oil containing wastewater treatment tank pry block mainly consists of a lifting pump, an oil containing wastewater treatment tankDosing deviceComposed of PLC control cabinet, manifold valve, etc.

&Nbsp& Nbsp& Nbsp; The oily wastewater treatment tank pry block is a new type of oily wastewater treatment equipment that integrates natural sedimentation, coalescence oil removal, flocculation vortex reaction, suspended mud purification filtration, titanium metal inclined plate coalescence oil removal, sedimentation and other technologies. The entire set of equipment has a processing efficiency of up to 90%, a short residence time (35-50% of conventional separation equipment), a small footprint, and adopts pressure type fully enclosed operation, stable operation, safety and reliability. It is often used as a pre-treatment equipment for oilfield produced water.

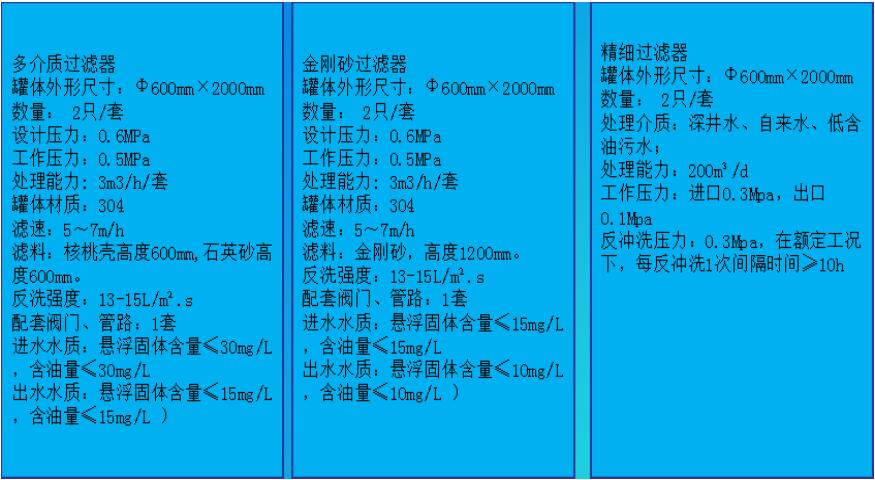

&Nbsp& Nbsp& Nbsp; 3. Filter pry block

&Nbsp& Nbsp& Nbsp; The filtering pry block consists of a dosing device, a multimedia filter, a diamond sand filter, a backwash pump, a water purification tank, and supporting pipelines and valves. This filter is suitable for fine filtration of oily wastewater treatment in oil fields, as well as for the treatment of other industrial wastewater.

&Nbsp& Nbsp& Nbsp; Multi media filters are two or more types of filtering media that, through reasonable grading, maximize the interception ability of filter layers with different densities, materials, and particle sizes. They have good filtering effects on the fine treatment of oil, suspended solids, iron ions, and colloids in wastewater, and have strong resistance to pollution and impact on oil and suspended solids, as well as strong regeneration ability of filter media. It has the characteristics of compact structure, easy operation, high degree of automation, smooth operation, high equipment filtration speed, high filtration accuracy, strong pollutant interception ability, thorough backwashing, and easy maintenance

&Nbsp& Nbsp& Nbsp; Diamond sand filter is a fine diamond sand filter material used as a filtering medium, which removes suspended solids in water through various functions such as resistance interception, gravity settling, and deep bed filtration. It has the characteristics of compact structure, easy operation, high degree of automation, smooth operation, high equipment filtration speed, high filtration accuracy, strong pollutant interception ability, thorough backwashing, and easy maintenance

&Nbsp& Nbsp& Nbsp; The PGR fine filter is composed of a rigid polymer PE sintered microporous filter tube, which is assembled into a single filtration tank. The filtration area is determined based on the treatment capacity of the foundation, and each filtration tank is assembled in series or parallel into a filtration device to meet the needs of different treatment capacities and media. The PE filter tube is made of hydrophilic and hydrophobic polymer materials, which have strong water absorption and belong to surface and deep filtration. It can not only be regenerated but also be reused, with a lifespan of generally 5-8 years

&Nbsp& Nbsp& Nbsp;

&Nbsp& Nbsp& Nbsp; Dosing device

&Nbsp& Nbsp& Nbsp; The dosing device is mainly used to inject various chemicals such as flocculants, scale inhibitors, corrosion inhibitors, and demulsifiers into the oily wastewater treatment tank and its system process

&Nbsp& Nbsp& Nbsp; The device mainly consists of a dosing tank, agitator, metering pump, etc.

&Nbsp& Nbsp& Nbsp;

&Nbsp& Nbsp; 4. Water purification tank pry block

&Nbsp& Nbsp& Nbsp; Mainly used for storing purified water and providing water source for injection pumps. Mainly composed of tank body, magnetic flap level gauge, pipeline, valve, etc.

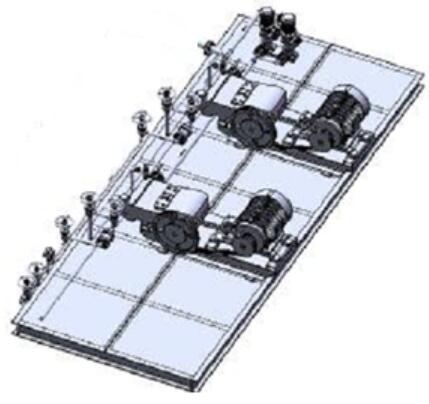

&Nbsp& Nbsp& Nbsp; 5. Water injection pump pry block

乐发lx&Nbsp& Nbsp& Nbsp; The water injection pump pry block mainly consists of water injection pump, feed water pump, pressure transmitter, variable frequency controller, manifold valve, etc. Inject qualified water into the injection well.

&Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp;